LANGUAGES

- Fuel cell trucks and fuel cell generators to use hydrogen

- Promotion of CO2 emissions reduction and energy conservation in convenience store distribution and operation

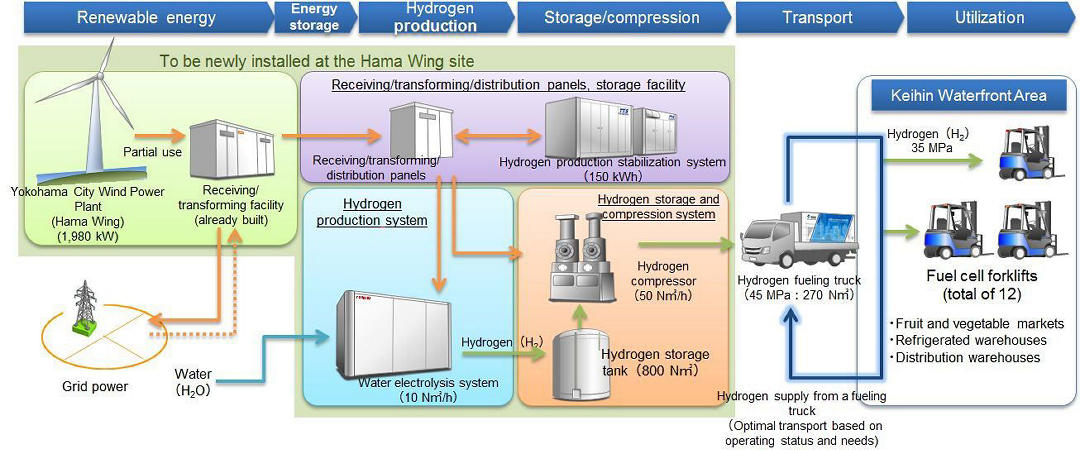

TORONTO, ONTARIO, June 6, 2018 - Seven-Eleven and Toyota recently announced details of a joint project to reduce CO2 emissions. Seven-Eleven and Toyota entered into a basic agreement in August 2017 regarding considerations toward energy conservation and carbon dioxide emission reduction in store distribution and operation. Toyota has been investigating the use of newly developed fuel cell trucks and fuel cell generators, and the project will be implemented in stages starting in 2019.

The project aims to introduce technologies and systems developed by Toyota in Seven-Eleven store operation and distribution to reduce CO2 emissions. Stationary fuel cell generators (FC generators) and rechargeable batteries will be introduced in stores managed centrally, by building energy management systems (BEMS) that raise the proportion of renewable energy and electric power derived from hydrogen used. A newly developed small fuel cell truck (small FC truck) will be introduced in the distribution process, aiming to achieve zero emissions of substances of concern including CO2.

The Seven & i Group is currently addressing five key issues*. Regarding non-wasteful usage of products, ingredients and energy, Seven & i is seeking to expand renewable energy use in line with the objectives of the Sustainable Development Goals (SDGs) adopted by the United Nations in 2015. Specifically, the Group plans to increase renewable energy use in stores to 20 percent and reduce CO2 emissions by 27 percent compared to FY 2013 by 2030. Seven-Eleven is taking measures to reduce CO2 emissions throughout its entire supply chain to meet its goals, focusing on renewable energy.

On December 7, 2017, Seven-Eleven opened the environmentally, user friendly Seven-Eleven Chiyoda Nibancho Store as a flagship of these initiatives. The second store, the Seven-Eleven Sagamihara Hashimotodai Itchome Store, opened on May 22, 2018, with renewable energy accounting for 46 percent of the store's electric power usage. Toyota technologies and systems that use hydrogen will be introduced in stores and distribution sites, with next generation stores using more renewable energy. Two small FC trucks are intended to be introduced within the Tokyo metropolitan region in approximately spring 2019, and operations of next generation stores are expected to commence in approximately autumn 2019.

*Seven & i Group's five key issues:

1) Providing Social Infrastructure for an Aging Society and Declining Population; 2) Providing Safety and Reliability through Products and Stores; 3) Non-Wasteful Usage of Products, Ingredients and Energy; 4) Supporting the Active Role of Women, Youth and Seniors across the Group and in Society; 5) Building an Ethical Society and Improving Resource Sustainability Together with Customers and Business Partners.

Toyota announced the Toyota Environmental Challenge 2050 in October 2015, which aims to assist in developing a sustainable society. Accordingly, Toyota is taking active measures to reduce CO2 emissions by promoting efficient energy use and alternative energy use, to address global environmental issues such as global warming, resource scarcity, and energy challenges. The current joint project aims to reduce CO2 emissions and conserve energy in Seven-Eleven store operation and distribution, and intends to support the accumulation and verification of new technologies and knowledge such as small FC trucks and FC generators.

Details of the joint project are set forth below.

1) Overview of the Joint Project

- The two companies will investigate ways to procure renewable energy and use energy efficiently, aiming to shift the energy used in stores to renewable energy and low-carbon hydrogen.

- Rechargeable batteries and stationary FC generators will be installed in stores and small FC trucks will be introduced for deliveries to reduce CO2 emissions. Performance, costs, durability, and CO2 reduction effects will be evaluated with the aim of promoting further deployment.

Deployment Plan

|

Area |

Item |

Introductory Stores and Areas |

Introduction Timing |

|---|---|---|---|

|

Store Operations |

Stationary rechargeable batteries |

Under consideration |

Autumn 2019 |

|

FC generators |

|||

|

BEMS |

|||

|

Chargers with power supply function |

|||

|

Distribution |

Small FC trucks |

Tokyo metropolitan region |

Spring 2019 |

2) Items to be introduced at stores

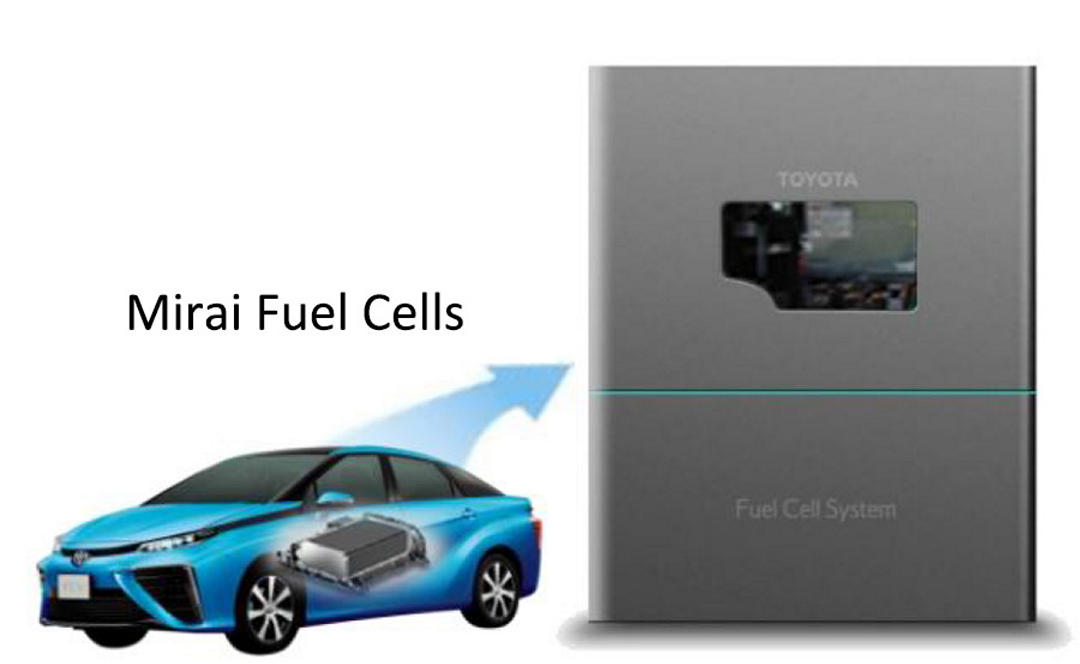

1) FC generator

- An FC generator will be installed in the store, generating electricity from hydrogen for store use.

- Boil-off hydrogen from the hydrogen station can also potentially be used.

- Efforts will be made to use hydrogen energy effectively, aiming toward the use of low-carbon hydrogen.

|

Rated output |

Approx. 10 kW |

|---|---|

|

FC stack |

Mirai stack |

|

Manufacturer |

Toyota Motor Corporation |

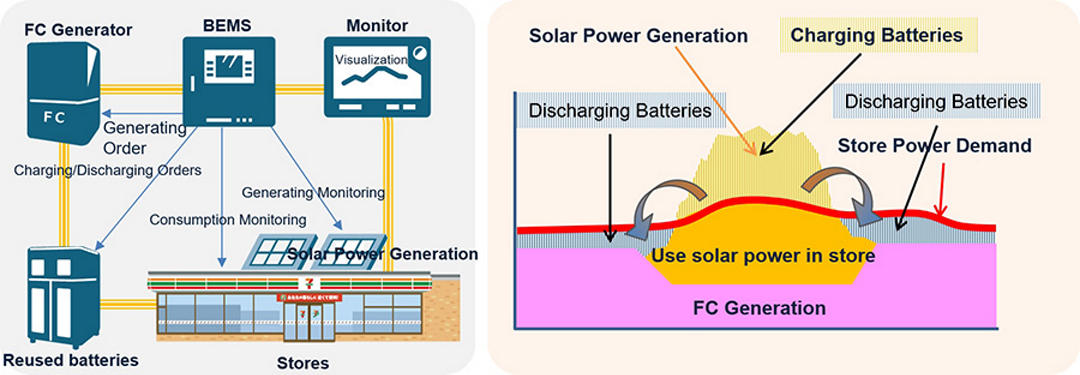

2) Stationary rechargeable batteries

- Rechargeable batteries for stable use of solar electric power, output weather dependent.

- When power is generated in excess of store demand, the batteries charge. When there is a shortage in power generated, the batteries discharge, raising the proportion of renewable energy use in the store.

- End-of-life batteries from hybrid vehicles will be used as rechargeable batteries.

|

Capacity |

10 kWh/unit (multiple units can be connected) |

|---|---|

|

Dimensions |

W 1,055 × D 1,230 × H 1,767 (mm) |

|

Weight |

Approx. 1,100 kg |

|

Manufacturer |

Toyota Energy Solutions Inc. |

3) Building energy management system (BEMS)

- Controls solar power generation, FC generators, and stationary rechargeable batteries, optimally supplying power to the store according to the store's power consumption status.

4) Charger with power supply function

- In addition to charging BEVs and PHEVs, the chargers can supply electric power from BEVs, PHEVs, and FCEVs to the store. When necessary, the charger can be operated with the BEMS to supply power from a BEV, PHEV, or FCEV that’s connected to a charger that’s also connected to the store, maintaining store operations and contributing to local recovery during a disaster.

|

Input/output during charging |

AC 200V, 5 kW/DC 50―450 V: Supports rapid charging |

|---|---|

|

Power supply from vehicle to store |

Max. 10 kW |

|

Dimensions |

W 270 × D 370 × H 1,600 (mm) |

|

Manufacturer |

Toyota Industries Corporation |

3) Items to be introduced in distribution (Tokyo metropolitan region) Small FC Trucks

- The trucks, equipped with Mirai FC units, do not emit any CO2 or other substances of concern during operation.

- The electric power generated by the FC unit powers the truck and serves as the power source for the refrigerator unit.

- When stopped, the FC unit supplies generated electricity to the refrigerator/freezer unit.

- The truck will be equipped with an external power supply function, for high-output, high-capacity electric power supply (maximum output of 9.8 kilowatts and maximum capacity of 235 kilowatt hours) and can be used as a power source during a disaster.

|

Dimensions |

L 6,185 x W 2,180 x H 2,970 (mm) |

|---|---|

|

FC stack maximum output |

114 kW/155 PS |

|

Hydrogen storage mass |

approx. 7 kg (3 tanks) |

|

Maximum payload |

3 tons |

|

Cruising range |

Toyota's target: 200 km Effective cruising range when used in the patterns anticipated for this project. Calculated by Toyota. |

About Toyota Canada Inc.

Toyota Canada Inc. (TCI) is the exclusive Canadian distributor of Toyota and Lexus vehicles. Toyota has sold over 5 million vehicles in Canada through a national network of 287 Toyota and Lexus dealerships. Toyota is dedicated to bringing safety, quality, dependability and reliability in the vehicles Canadians drive and the service they receive. TCI’s head office is located in Toronto, with regional offices in Vancouver, Calgary, Montreal and Halifax and parts distribution centres in Toronto and Vancouver. Toyota operates two manufacturing facilities in Canada. Having produced more than eight million vehicles, popular Canadian models built at these facilities include Toyota RAV4, Toyota Corolla, Lexus RX 350 and RX 450h hybrid.

###

Every effort has been made to ensure the product specifications, equipment, and content on this site are accurate based on information available at time of publishing. In some cases, certain changes in standard equipment or options may occur, which may not be reflected online. Toyota Canada reserves the rights to make these changes without notice or obligation.